High compressive HDPE crane outrigger pads strength UHMWPE plastic crane sleepers

Product description of Light weight Crane outrigger pad:

Plastic Crane Outrigger Pads put under the support-leg of Truck Crane, Crawler Crane, Rough Crane, Boom Pump, Concrete Pump, Fire Truck, Utility Truck, Tree Trimmer, Any Type Of Aerial Equipment and so on. for making the machine work safely!

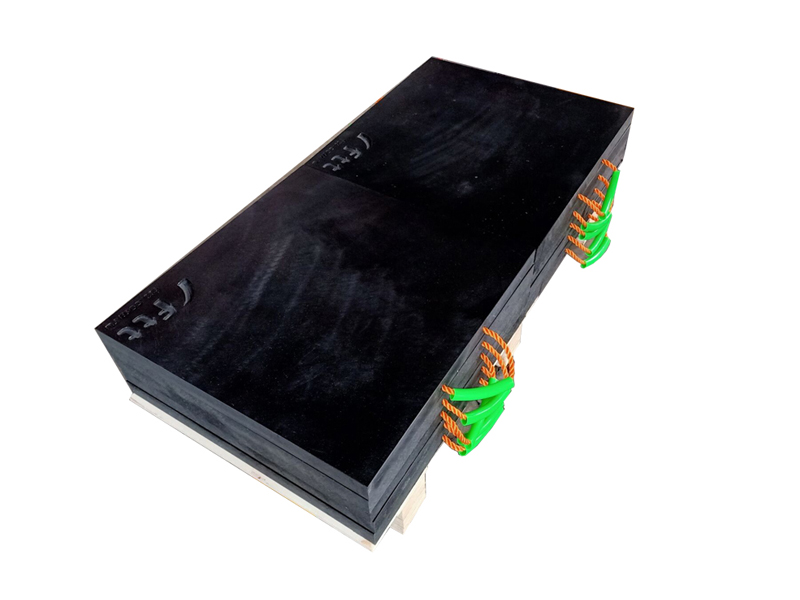

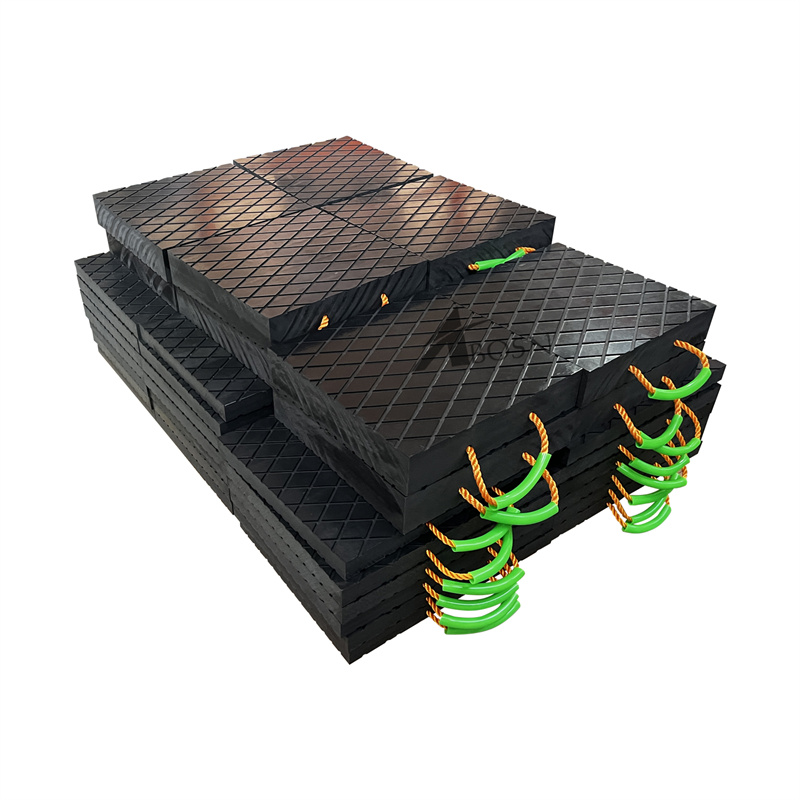

ABOSN Outrigger Pads are manufactured using engineered UHMWPE, providing superior strength-to-weight ratio than the timbers commonly used to support outriggers and crane arms. These lightweight, usable pads provide a large non-slip surface area for absorbing load - minimising movement and sinkage. They can be used to stabilise outriggers, crane arms, scaffolding structures, uprights and angled loading.

Xinxing Outrigger Pads will not splinter, warp, delaminate or breakdown in the harsh environment. The pads are engineered to bend but not break and come with a Lifetime Replacement Guarantee. Featuring a non-slip textured surface, these pads are built to the highest safety standards and are very easy to use with convenient safety rope handles.

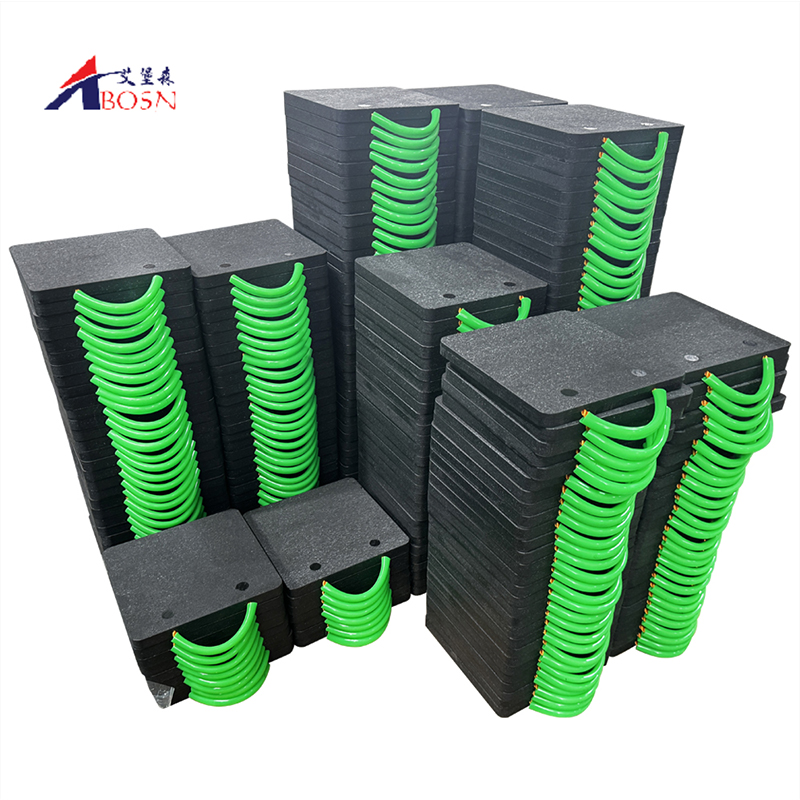

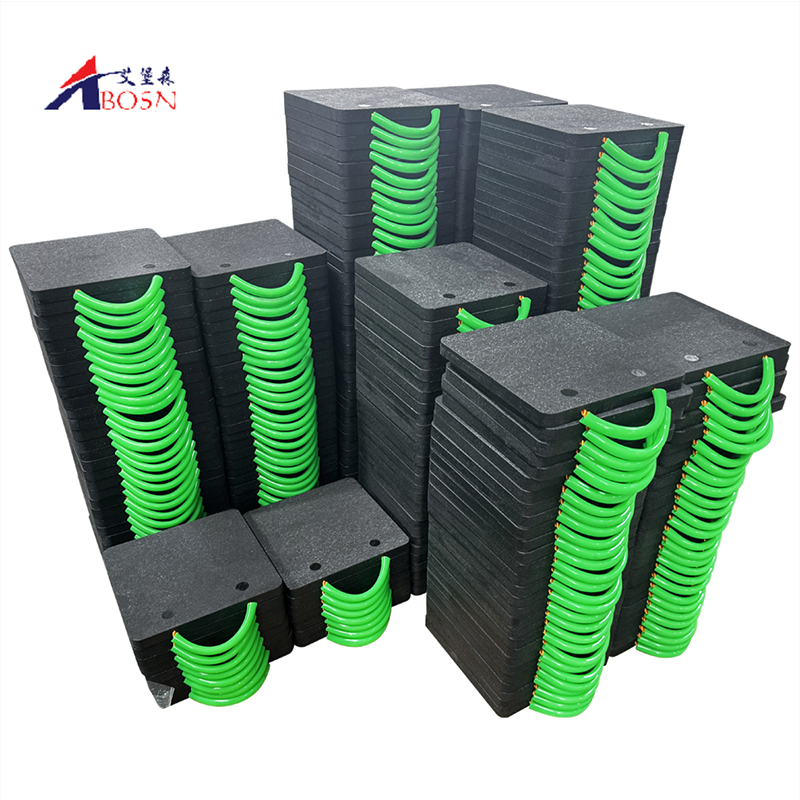

ABOSN Outrigger Pads are the only engineered quantifiable and rated outrigger pads available today and come in a range of sizes to suit every job.

Features of Light weight Crane outrigger pad:

* Do not absorb moisture and will not swell up over time due to exposure outdoors.

* Good impact intensity, Do not lose their impact strength over time.

* Good breaking elongation,so they will bend but not break under extreme loads.

* Will not rot,crack,splinter, or absorb moisture, safer to use in the field compared to other wood based pads.

* Can work in in adverse weather conditions.

* Durable & Long Lasting, Cost Efficient compared to Steel or Aluminum.

* Amazingly light compared to steel pads, and easier to mount, replace.

* Non-stick surface, easy to clean.

* Corrosion and chemical resistant.

* Lower maintenance costs.

* Storage-Friendly.

CHOOSE THE CORRECT SIZE OF OUTRIGGER PADS?

STEP 1: DETERMINE THE LOAD Each outrigger pad should support at least 40%-80% of the total equipment weight (self-weight, burden / persons lifted, counterweight). This can be 70%-80% of total weight for a mobile crane which rotates around its axle during operation or 40%-50% for more static equipment.

STEP 2: DETERMINE THE TYPE OF SURFACE PADS WILL BE USED ON Use our load chart to select the right size and thickness pad to use on hard & medium hard clay soils. Consider larger and thicker pads or a combination of pads if you plan to use the equipment on soft clay and fine sand.

STEP 3: USE THE PADS IN THE RIGHT WAY The outrigger should be centred on the pad when in use. The pads should not be placed over voids and loose materials that can be washed away in the rain.

Contact us

E-mail:fiona@dzabosn.com

Phone/Whatsapp:+86 175 5341 8926